Expert in plastics injection molding, in our workshop in China we produce all types of plastic technical and appearance parts from small runs to mass production. We have fully automated injection presses from 70 to 1200T. The injected parts can then be assembled on our assembly lines and finalized by various finishing and decoration operations (metalizing, painting, inserts, etc.).

We work with all types of thermoplastic and elastomer materials according to customer specifications: ABS, PC, PMMA, TPE, PA, TPU, POM etc., with or without loading. We master different injection processes depending on the characteristics of the parts to inject. Our design office, a department central to our organization, ensures the optimization of the part whether it is at the prototyping or the molding by injection stage. In addition, it takes charge of the design of the plastic injection molds and the 3D drawings will be given to you. The molds will be manufactured in our tooling workshop and maintained in our dedicated and laid-out storage room.

Plastic injection molding know-how

Design office

Our integrated design office is in charge of the optimization of the part and the design of the plastic injection molds. It can intervene upstream of the prototyping phase.

Prototyping

Upstream of series production, we offer different fast prototyping technologies. These prototypes allow us to test a pre-series, and to perform visual, functional and mechanical tests.

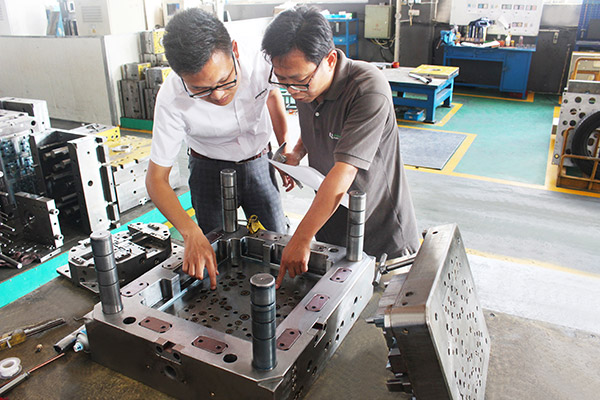

Injection molds

There are no good parts without good injection tools. You invest in a quality mold made to European standards. The design, the manufacture and the maintenance are performed internally in our mold workshop. We guarantee the servicing.

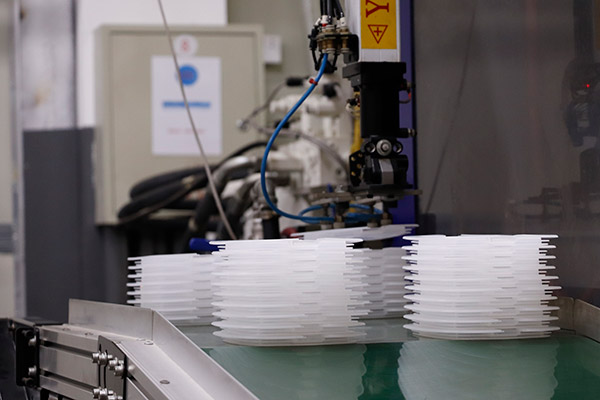

Injection molding

Once the manufacture of the tools is finished, we launch the production in our injection workshop. Our production lines are completely automated, and each batch is checked. Our expertise concerns as much injection as bi-injection; over-molding, gas assisted injection.

Decoration

We provide different finishing operations (marking, stamping, screen printing, etc.) and the decoration of injected plastic parts to give the desired appearance.

For more information on our plastic injection molding service, consult our customer case studies and our showroom.

Leave A Comment