A mold (or tool) for plastic injection is used in the framework of the series production of plastic parts. The design and manufacture of injection molds is a strategic step for obtaining quality parts throughout the project. This is the reason for which we have chosen to in-source this work of design and manufacture, directly in our factory.

All the tools that we manufacture in our workshop comply with European Standards. You invest in a quality production asset. We benefit from the total control of their manufacture: design, purchasing, scheduling, machining, adjustments and maintenance. You receive and can check the 3D mold file and you remain the owner of your tool until its end of service life. Depending on your product specification, we can manufacture any type of injection mold depending on the quantity, the type of parts to produce, and the choice of materials: hot channel molds, multi-imprint molds, dual-injection molds, over-molding molds, gas-assisted molds. Our manufacturing lead-times vary generally from 5 to 8 weeks.

Our mold workshop

3000m²

Mold workshop

250

Capacity/year

200

Inspection points

Maintenance

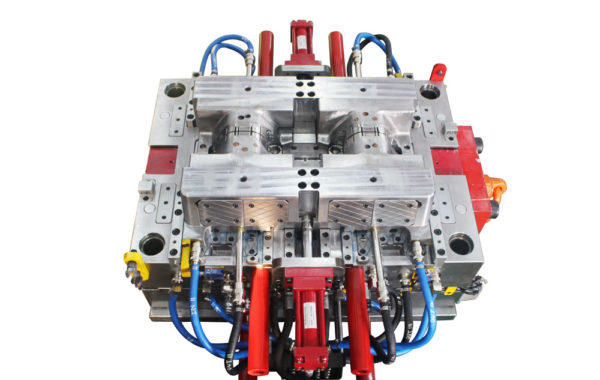

Manufacturing workshop for plastic injection mold

Our plastic injection mold manufacturing workshop is equipped with the latest generation machines and is organized around a systematic process control. Our tooling team is comprised of experienced plastics engineering technicians. Checks are performed during the different steps of the project. We guarantee the traceability of all components and sourcing from our rigorously qualified suppliers and partners (steels, standard components, etc.).

Machining

Our machining center is equipped with 6 CNC machines (Makino, Fanuc), 6 sinker EDM machines and 6 wire cutting machines. The whole manufacturing process is monitored by our ERP.

Check

Dimensional and mechanical checks are performed on all tooling components. More than 200 inspection points are checked.

Adjustment

After the initial tests, we perform modifications and improvements required for finalizing the parts and for making the mold industrially usable.

Manufacturing steps of a plastic injection mold

We present below, the different steps in the manufacture and use of your injection mold.

Part optimization

After analysis of your specification, our design office performs an exhaustive analysis of your part design in order to ensure optimization.

Tool design

Following the analysis of the part, our design office designs and produces the plans for the injection tools needed for the production of the plastic parts.

Tool manufacture

We launch the machining of the plastic injection mold in our mold workshop and we rigorously check every detail and element of it.

Validation of samples

We produce samples of your plastic parts for the different validation steps. We perform different adjustments before launching series production.

Production launch

The mold goes into series production, we immediately start additional injection moldings of your plastic parts. We then perform different finishing and assembly operations if necessary.

Preventive maintenance

During the whole service life of your injection mold, we perform all servicing and maintenance operations in order to ensure the longevity of your productions.

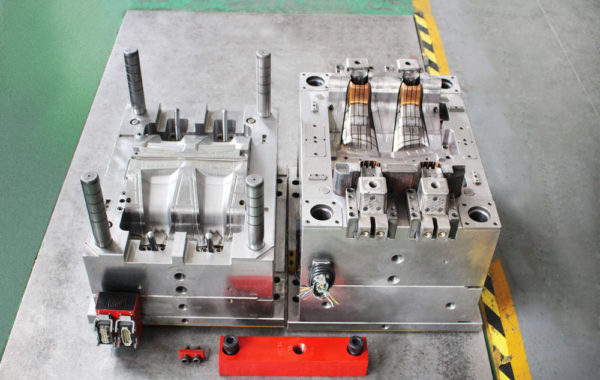

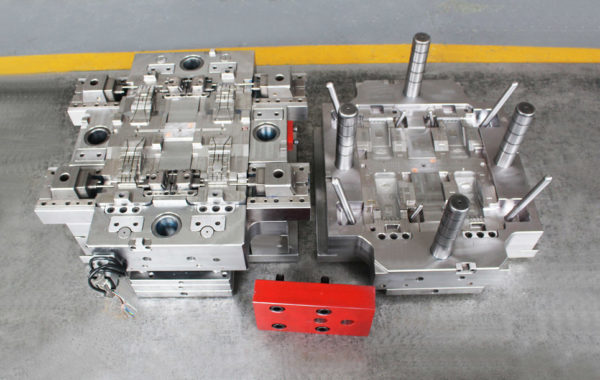

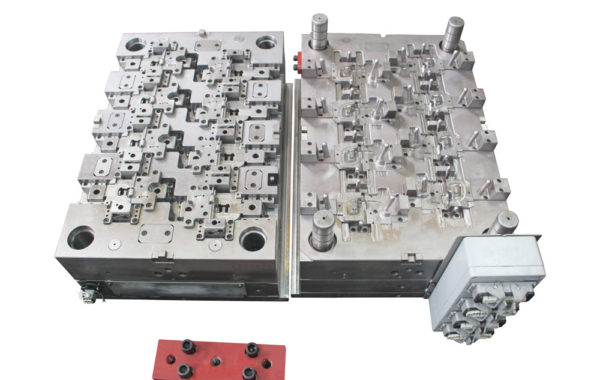

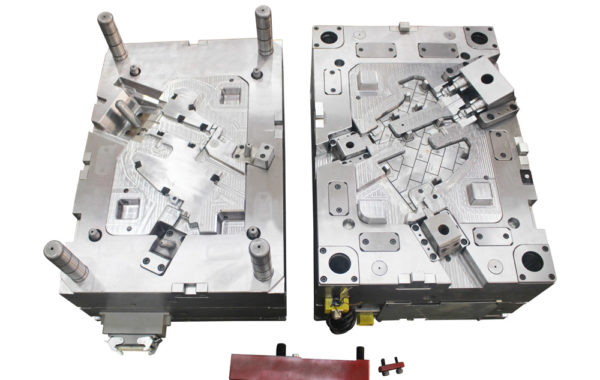

Examples of manufactured plastic injection molds

Below are a few examples of injection molds that we have manufactured. For molds intended for export, you can also consult our specialized subsidiary, Unimold Asia.

Do not hesitate to contact us to know more about our know-how in China. We are ready to listen to assist you in your plastics injection project.

Leave A Comment