Molding by plastics injection has been at the heart of our business for 15 years. Our capacities in China allow us to produce any type of plastic part and to offer a very wide choice of thermoplastic and elastomer materials (ABS, PC, PMMA, TPE, PA, TPU, POM etc., with or without loading). We have great experience in injection for different business sectors: automotive, medical, foodstuffs, electronics, sports & recreation, etc.

The transition between our mold manufacturing workshop and our injection workshop is done smoothly and we can launch the series production of the plastic parts without additional delay. We work all types of volumes, from small runs to mass production of technical and appearance parts. Your main contact person stays the same throughout the project. Our production times vary depending on the type of mold (multi-imprint, dual-material, etc.) and the complexity of the parts. In general, the first parts are injected as of 5 to 8 weeks after launching the injection project. The injected parts can then be assembled on our assembly lines and finalized by various finishing and decoration operations. Between each production cycle, the mold is checked then stored in our dedicated space until the next parts manufacturing cycle.

4000m²

Injection workshop

Robotized

machines

Production

stability

Ease of

communication

Plastic injection molding workshop

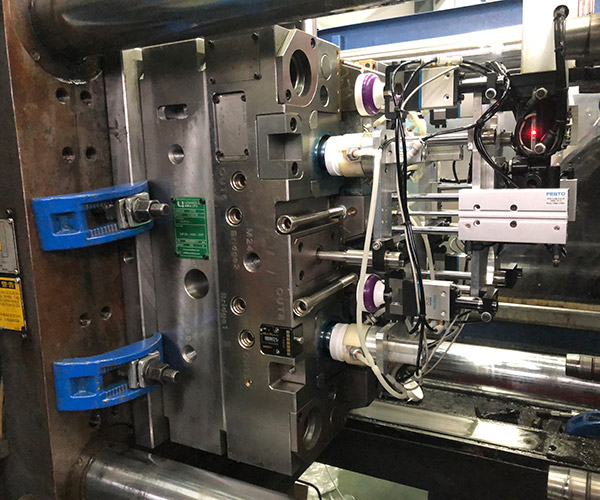

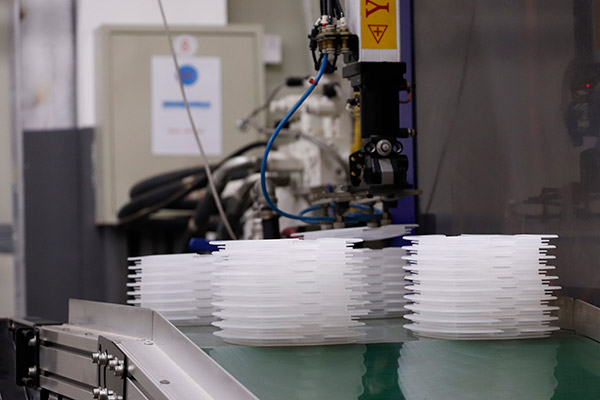

Our injection molding workshop is equipped with an automated fleet of thermoplastic injection presses from 70 to 1200T. We produce series from several thousand to several million pieces. Our team is comprised of expert plastics engineering technicians in particular with several installer-adjusters and machine operators. All our presses are robotized with gripping hands and independent peripherals (cooling unit, temperature controller, etc.) for continuous 24/7 production. The material unit directly supplies the presses and each one has a colorimeter to ensure constant coloring for all productions.

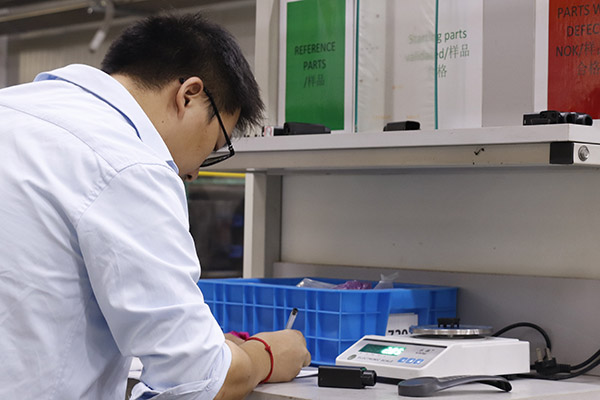

We follow a production and quality control register in order to have proper control and monitoring of faults on injected parts. For the plastic raw material, we have established rigorous traceability on the sourcing and use of it during the production (management of discards, re-grinding, etc.). We have an inspection center equipped with conventional tools (gages, Vernier calipers, etc.) and are able to install specific inspection tools like dimensional templates.

Injection

Entirely automated Injection machine fleet, materials unit and independent peripherals, colorimeter. Large choice of thermoplastic materials.

Inspection

The inspection of injected parts and the establishment of quality control documentation (PPAP, CP/CPK, dimensional report)

Traceability

We supply material certificates as guarantee on the materials used. Internal storage and maintenance of the molds.

Our assistance with plastic injection molding

Plastic injection molding is a specific manufacturing process and we assist you right from the start for the success of your project. The analysis of moldability (and rheology) of your 3D concept by our design office, is an important step. In fact, it allows possible problems to be identified and eliminated (injection point, ejection, voids, counter-clearances, wall thicknesses, etc.) on your parts. The design of the tooling comes directly from it and in particular, 4 characteristics are to be anticipated: the point of injection, the layout of the ejectors, the sealing plane line and the clearances.

We also guide you on the choice of materials. We have access to a hundred thermoplastics according to your needs. The choice of it will be defined depending on your specifications, mechanical properties, its environment and the necessary certifications. Closest to your many needs, we master the main processes of plastic injection molding: single-material molding, dual-material molding, gas assisted injection, insert over-molding. For small runs in the proper material, we offer injection with a mold prototype.

Bi-injection / 2k molding

The bi-injection molding process consists of injecting two materials of different hardness or color for the same part.

Insert over-molding

This allows an exterior plastic or metal element to be inserted (screw thread, shafts, etc.) into the injected plastic.

Example of injected plastic parts

Below are several examples of injected parts and sub-assemblies which we have manufactured. Boxes, pumps, drones, packaging, cosmetics, etc.

Sector: industrial

Part: pump

Material: PA66 GF

Finish: Matte Grain

Assembly: assembly with metal inserts

Industry: industrial

Material: PA66 GF and PC

Finish: texture and mirror polishing

Assembly: assembly of the window pane

Industry: food

Type of part: lid

Material: PP

Finition: mirror polishing

Assembly: clips and joints assembly

Do not hesitate to contact us to know more about our know-how in China. We are ready to listen to assist you in your plastic injection molding project.

Leave A Comment