WHAT IS INSERT OVERMOLDING?

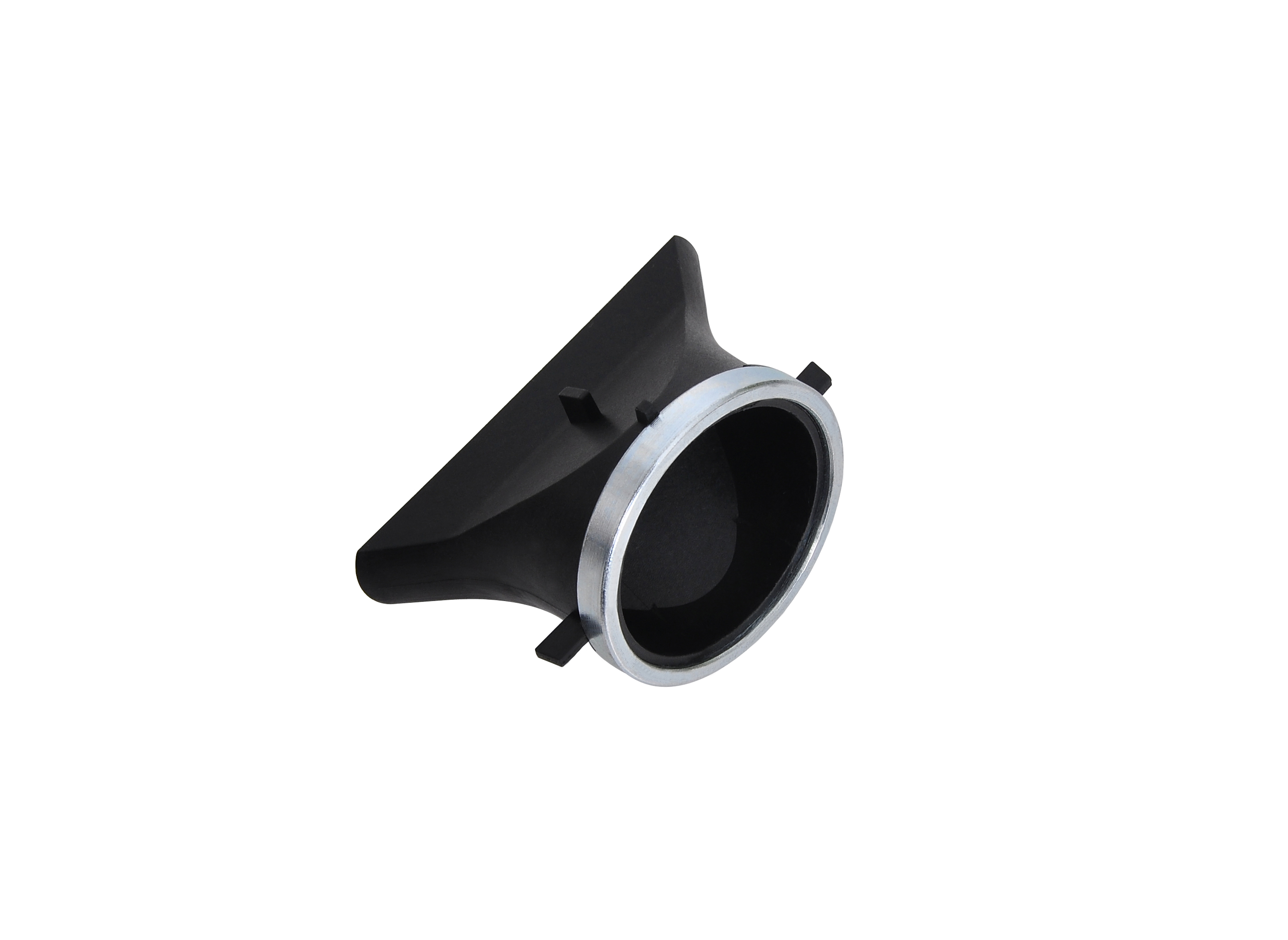

An insert overmolding operation consists in molding an insert on a plastic part already molded. In a manual or automated way, the insert is positioned in or on the initial plastic part, itself positioned in an injection mold (or vacuum casting mold in prototyping). Then, a plastic material (polymer, thermoplastic, elastomer, etc.) is heated and injected in a liquid state into the mold containing the part and the insert. Thus, the resin will cover all or part of the insert and will attach itself by chemical bonding to the initial plastic material, in order to fix or encapsulate the metal insert by mechanical bonding, after cooling.

What is an insert in plastics processing?

In plastics processing, during the manufacturing process of a plastic part, an insert is a metallic element (or other material) that the manufacturer inserts to give this part a property or a functionality defined in the specifications. This insert can be manufactured by foundry casting, metal machining, welding, sheet metal work or other metalworking techniques.

Once in place, inserts can be used to reinforce the plastic part, to ensure compatibility for assembly, connection or attachment to another part, or for other technical purposes. However, an insert can also be an electrical or electronic component that is molded or overmolded in plastic to protect or insulate it.

The various types and materials of inserts

A metal insert can be made of brass, steel or aluminum, like most injection molded inserts, but there are inserts made of other metals and materials. In order for the overmolded plastic to bond to the initial part of the plastic, the shape of the insert is most often threaded, serrated, grooved, punched, or some other pattern that allows for a mechanical bond after molding. More precisely, the dimensions and shapes of the inserts depend on the characteristics, properties and functionalities assigned to them in the manufacturer’s specifications, as early as the 3D modeling stage.

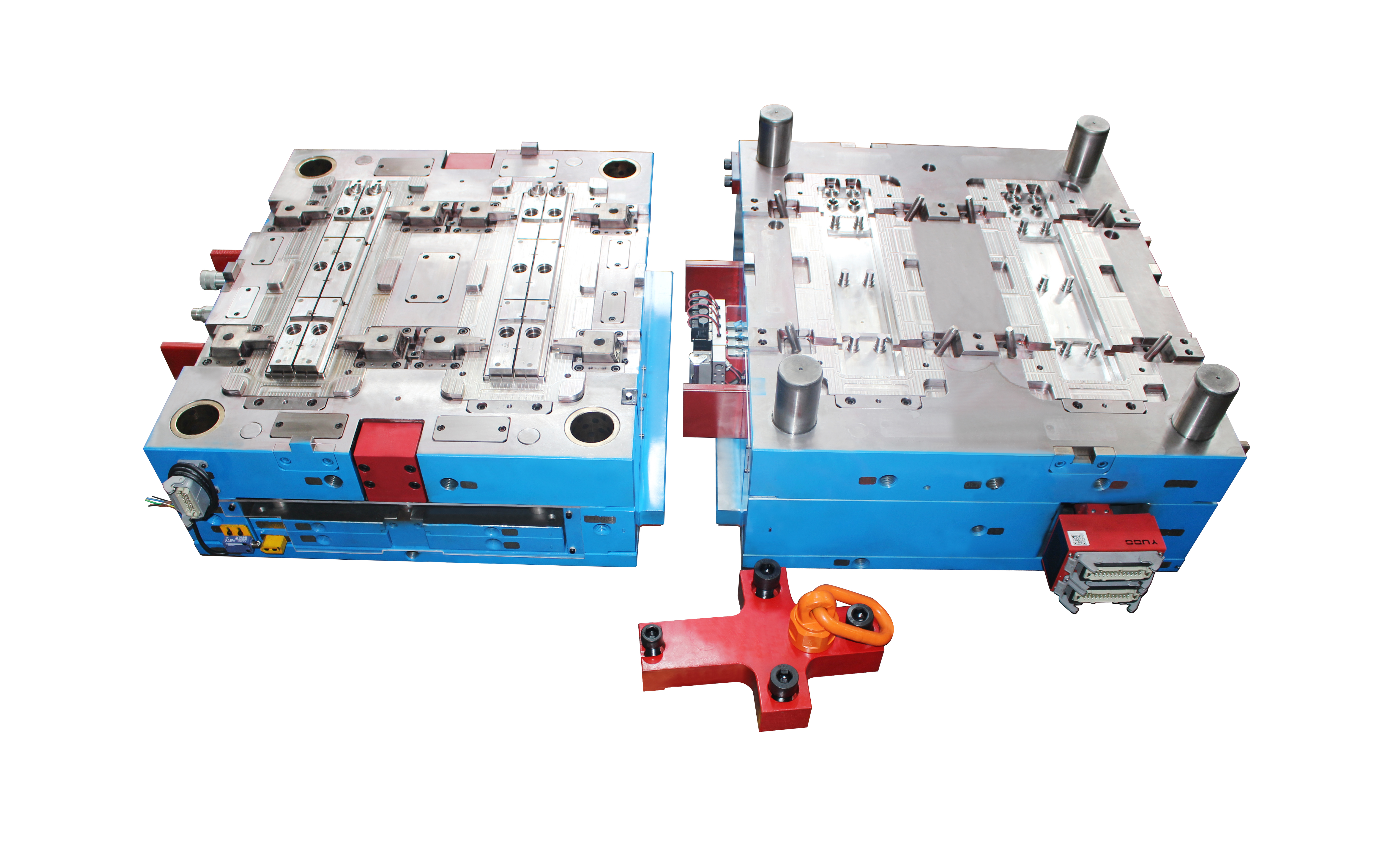

FPM Injection, your expert in injection molding and insert overmolding

Specialists in plastic injection molding and overmolding of metal inserts, we have our own design office and our plastics factory in China for rapid prototyping or pre-production, small series, medium series or large series. FPM Injection‘s advanced know-how is at your disposal, and we can offer you a full range of solutions: 3D modeling, CNC machining, mold making, molding of technical parts and composite parts, insertion of metal parts, assembly of complex parts, decoration, finishing of plastic parts. If you would like to know more or ask for a quick quote to request our expertise as a plastic mold maker on order or as a subcontractor, contact us.

Comments are closed.