Plastic prototyping is an important step in the development of a project for producing a part by injection molding. Manufacturing a prototype (single or small run) in fact, allows a concept to be validated, different tests and validations to be run or pre-series parts to be produced (for marketing needs, product launch, for substitution series, etc.). Plastic prototyping offers the possibility of performing modifications and adjustments more quickly and in a less onerous fashion, than during the industrialization phase.

Depending on your specifications, we are able to offer you the main rapid plastic prototyping services: 3D printing, CNC machining, Vacuum casting or prototype mold for plastic injection. Production times and manufacturing costs are much lower compared to series production. Our design office works from your CAD designs (generally 3D files in .STEP or .IGS format).

Main reasons for plastic prototyping

Visual validations

Produce prototype plastic parts in order to test different versions, to validate the shape and the aesthetics, to compare different finishes.

Functional validations

Produce prototype plastic parts in order to test the functioning and subject them to actual stresses in use. Ideal also for pre-certification tests.

Mechanical validations

Produce prototype plastic parts in order to test the mechanical properties and robustness (traction, compression, durability, etc.).

Assembly tests

Produce prototype plastic parts in order to identify possible errors of design and functionality of the unit. We can perform assembly tests internally.

Prototype mold for low-volume plastic injection molding

We have developed a thermoplastic injection molding solution specially adapted to small run and pre-series production (quantity 100 to 1000+ pieces). These parts are obtained using a prototype mold (or fast tooling) in an interchangeable imprint housing. It is an intermediate solution between series production and rapid prototyping. It requires an investment and longer lead-times than prototyping but allows parts to be obtained equivalent to the series ones in the “correct material”. The robustness, mechanical properties and industrialization information on the injected parts are identical. For small run production (less than 200 pieces), we can recommend vacuum casting technology (or vacuum duplication). Insert over-molding is possible with these plastic prototyping processes.

Examples of prototype parts

Below are several examples of custom prototype parts that we have manufactured. For more information on our plastic prototyping service, you can look at our subsidiary, Prototech Asia, specialized in rapid prototyping.

Industry: IOT

Type of part: connected wristband

Material: PU

Finish: polishing

Assembly: plastic assembly

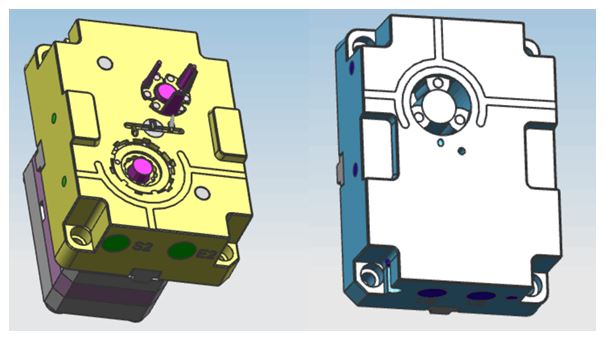

Industry: industrial

Type of part: case

Material: ABS et TPE

Finish: charmille

Assembly: assembly of the legs

Do not hesitate to contact us to know more about our know-how in China. We are ready to listen to assist you in your plastic injection and plastic prototyping project.

Leave A Comment