Expert in plastic injection molding

FPM Injection assists you in the design and manufacture of your parts and sub-assemblies in plastic materials. Our integrated offer of service in China provides you with a trusted collaboration with a single plastics engineering sub-contractor

Plastic prototyping

We master the main technologies of fast prototyping, the essential step prior to the mass production of plastic products. Producing a prototype or a small run allows you to validate a concept, to make different tests and validations or to produce small/pre-series in the correct material.

Mold production

In our factory in China, we have in-sourced the production of plastics injection molds and tools. Depending on your specifications, we can produce any type of series mold (bi-material, multi-imprint, over-molding, etc.) and provide it with servicing and maintenance throughout the production period.

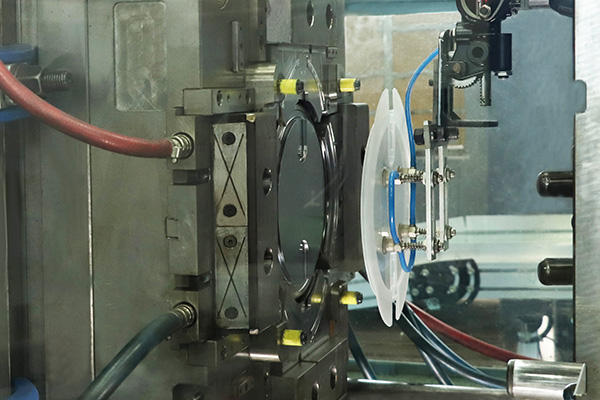

Plastic injection molding

Plastic injection molding is at the heart of our business. Our injection workshop is equipped with a fleet of automated presses from 70 to 1200T for producing thousands of parts. In China, we produce any type of plastic part and offer a wide choice of thermoplastic and elastomer raw materials. We perform the decoration of your injected parts.

Assembly

Our workshop is equipped with mounting lines for the assembly of plastic parts and sub-assemblies. We also perform the integration of components and supplies (inserts, gaskets, fasteners, etc.) as well as packing and packaging. Our purchasing office performs the sourcing and certification of the different elements from our network of suppliers.

Plastics sub-contracting in China

FPM Injection, a French industrial partner, has been a specialist in plastics injection in China for more than 15 years. Our factory ( 8200m²) itself is certified ISO 9001 and is situated near Shanghai in the province of Zhejiang, in Yuyao. At this time, we have a bit more than one hundred employees. Initially specialized in the production of injected plastic parts (technical and appearance parts), we have enlarged our offer of services from the design of parts to the industrialization of finished products.

A global plastics solution, allowing us to master and monitor all of the steps of design, manufacture and assembly of your plastic parts and sub-assemblies. We have optimized our means and capacities for the production of plastic parts in order to best meet your requirements and specifications. Our international team, composed of a French management, has great experience in the field of plastics engineering and in sub-contracting in China. There is no competitiveness without product quality, so we work to the European standards and withe perfectly defined internal and external process control and traceability.

Working with FPM Injection is the guarantee of transparent cooperation allowing quality products to be developed in China easily and safely.

Collaborating with FPM INJECTION

Irrespective of the level of progress on your project, we are ready to listen to your needs and to work on it rapidly. Being specialized in the design of global solutions, we provide our experience to bring you technical solutions specially adapted for the success of your project (design office, choice of materials, injection solution, etc.). A single contact person (in French or in English) will assist you throughout it. We work in all types of business sectors: automotive, medical, cosmetics, industrial, electronics, IOT, sport, etc.

We invite you to contact us for any study of moldability of your parts and any request for information, or if you wish, you can come and visit our factory in China.

In collaboration we guarantee you

Safety

European management with more than 15 years of experience of plastics engineering in China; a personal factory with control over the whole production chain.

Ease of working

With a perfectly transparent project head relationship, we guarantee constant visibility throughout your plastics injection project.

Quality

In order to guarantee the quality and sustainability of your project, we have put a process in place, according to European standards and systematic and rigorous quality control.

Competitiveness

Thanks to our lower cost of labor and a network of qualified, efficient suppliers, we are able to offer you a competitive service.

Lastest news

THE COMMONLY USED MATERIALS FOR PLASTIC INJECTION MOLDING

The following is an overview of the common plastic injection molding materials used for plastic ...

Read morePrototyping and industrialization of connected cases

At FPM Injection, we regularly support our customers from the prototyping phase through to serial ...

Read moreEnd of year celebrations and Chinese New Year

The end of year celebrations is approaching fast and we hope you have a wonderful time with your ...

Read moreOur customers say

“I have worked with FPM injection for a number of years and everything goes well. They inject a part of my range and take care of the integration of certain components.”

“We are delighted and very satisfied with the partnership developed with FPM Injection. Indeed, when there was a difficult project, the team formed around Romain showed it was ready to listen and to understand our needs. The rapid response, the strength of the proposal and the activation of the whole team were remarkable. I especially appreciated the final phases of the development of a complex mold… Our ambitious goals were met.”

“FPM is a valued partner for both the mold and serial production part. It is an essential player in our high value-added drone business. They can support us on various subjects, from the development and production of the plastic parts to the integration into a finished product, considering assembly constraints and the environment in which our products evolve. FPM is a strategic partner also on the assembly of finished elements and operational management” “Thanks to their competence and their mastery of the Asian market, we benefit from the expertise of a factory with European standard and a peace of mind on the qualitative aspect”

Comments are closed.